With high optical damage resistance and homogeneity, MgO:LN wafers (upto 4 inches in diameter) are now being used in new applications in the optical network, blue laser and other markets.

SINGLECRYSTAL MAGNESIUM FREE

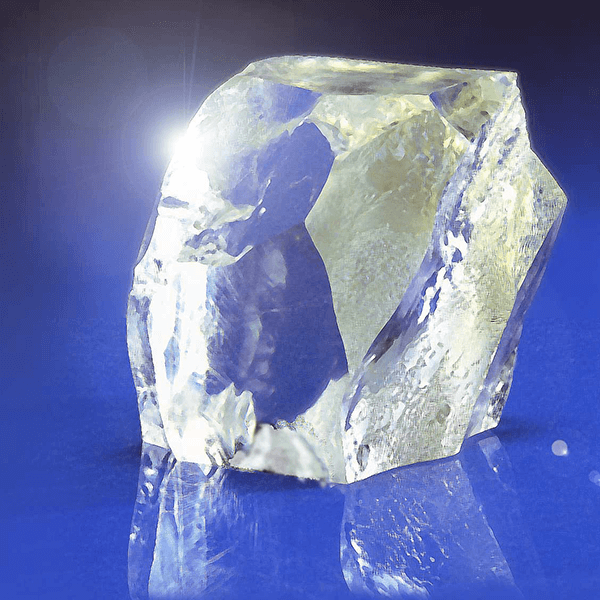

Over this time the focus has been on optimising growth conditions and improving raw material purity (to avoid impurities such as Fe) with the result that sub-grainboundary free material is now readily available with excellent transmission characeristics. At shorter wavelengths, for example with blue lasers, the photorefractive effect must also be considered – here we can see local changes in the refractive index in areas under laser illumination which lead to optical damage.ĭevelopment and manufacture of MgO:LN has taken place since 1985. In general, the main requirement for MgO:LN for optical applications is a stable and homogeneous refractive index ( Erbium doping is also available). The characteristics of Magnesium doped lithium niobate are resistance to optical damage, low absorption loss and no refractive index fluctuation within the crystal. To control these phenomena, high optical damage threshold materials have been developed, using magnesium as a dopant. It is well known that applying a short wavelength (blue or green) laser to lithium niobate causes "optical damage" through the photo-refrective effect, and also refractive index fluctuations. Magnesium Doped Lithium Niobate for PPLN - (Periodically Poled Lithium Niobate) To improve the quality of optical grade, we aim to achieve sub-grain boundary free wafer. This is a very simple way to control the crystal quality to determine whether whether Optical or Saw grade. use of single crystal elastic constant data and employing Kudriavtsevs. Quality Control level of refractive index Mg + O would have a lattice energy (and, therefore, a melting point) similar. For quality control purposes, these figures are a measurement to achieve high quality as standard.

There is significant correlation between refractive index and composition. To analyze the effect of the initial orientation in the activity of twinning and texture development, magnesium single crystals were rolled at 400 C. A polycrystalline high-density magnesium fluoride, fabricated into plates or shapes by hot-pressing, exhibits high in-line transmittance from 2.5 to 6.0 m, and single-crystal magnesium fluoride extends from 0.1 to 6.0 m.

Quality Control level of Curie temperatureĢ Evaluation Using Refractive Index- Related to the composition of LiNbO3 / LiTaO3 The Roditi International Corporation LtdĮvaluation and Quality Control for Optical Wafers 1 Evaluation Using Curie Temperature - Related to the composition of LiNbO3 / LiTaO3.Strain localization inside contraction twins was observed, and consequently, non-basal grains nucleated inside these twins and weakened the final basal texture only in orientation 1.

The active twin variants in orientation 1 aligned the basal plane ~30° from the sheet plane and caused a weaker basal texture compared to orientation 2, where the twin variants aligned the basal plane almost parallel to the sheet plane.

The initial single crystals were turned into polycrystals, where most grains had their c-axis almost parallel to the ND, and this reorientation was explained by extension twinning. The microstructure and texture evolution were characterized by X-ray diffraction and Electron Backscatter Diffraction (EBSD). After rolling, all the samples were quenched in water to retain the microstructure. The samples were rolled at 30%, 50% and 80% of thickness reduction. For orientation 1, the 11 2 ¯ 0 direction was parallel to the normal direction (ND), and for orientation 2, it was parallel to the 10 1 ¯ 0 direction. In both orientations, the rolling direction of the sheet (RD) was parallel to the c-axis. To analyze the effect of the initial orientation in the activity of twinning and texture development, magnesium single crystals were rolled at 400 ☌ (nominal furnace temperature) in two specific orientations.

0 kommentar(er)

0 kommentar(er)